Services

Our unique team at NextGen is driven to push our equipment and tooling to the limits to find better, faster and more accurate ways to deliver our product to our customers.

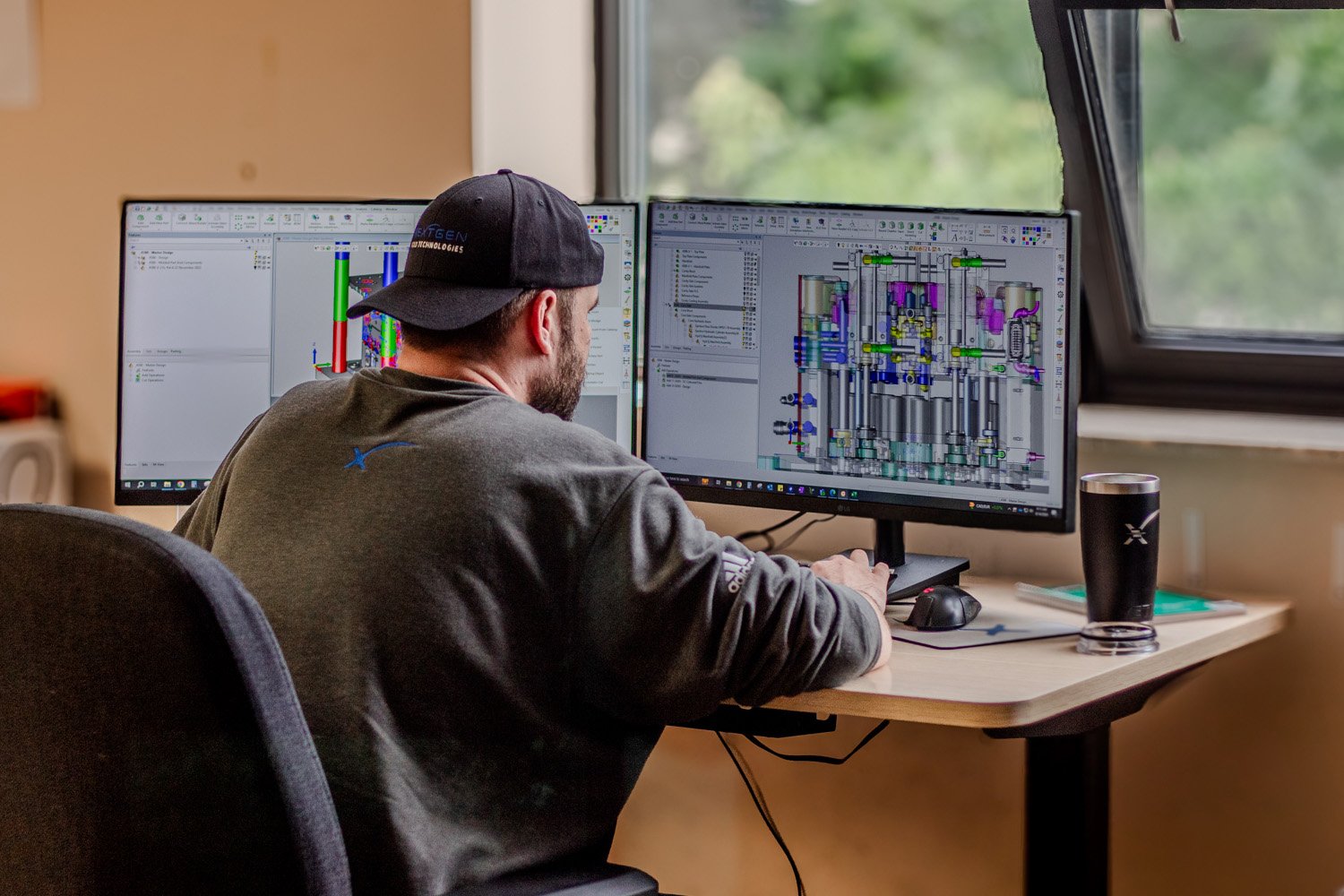

Feasibility

& Design

Utilizing Cimatron CAD software, our team of highly skilled surfacers and designers is dedicated to ensuring that both part and mold designs yield a superior product for the end user. Each mold undergoes a rigorous design process to implement best practices, optimizing customer cycle time and facilitating future mold maintenance to ensure customer success.

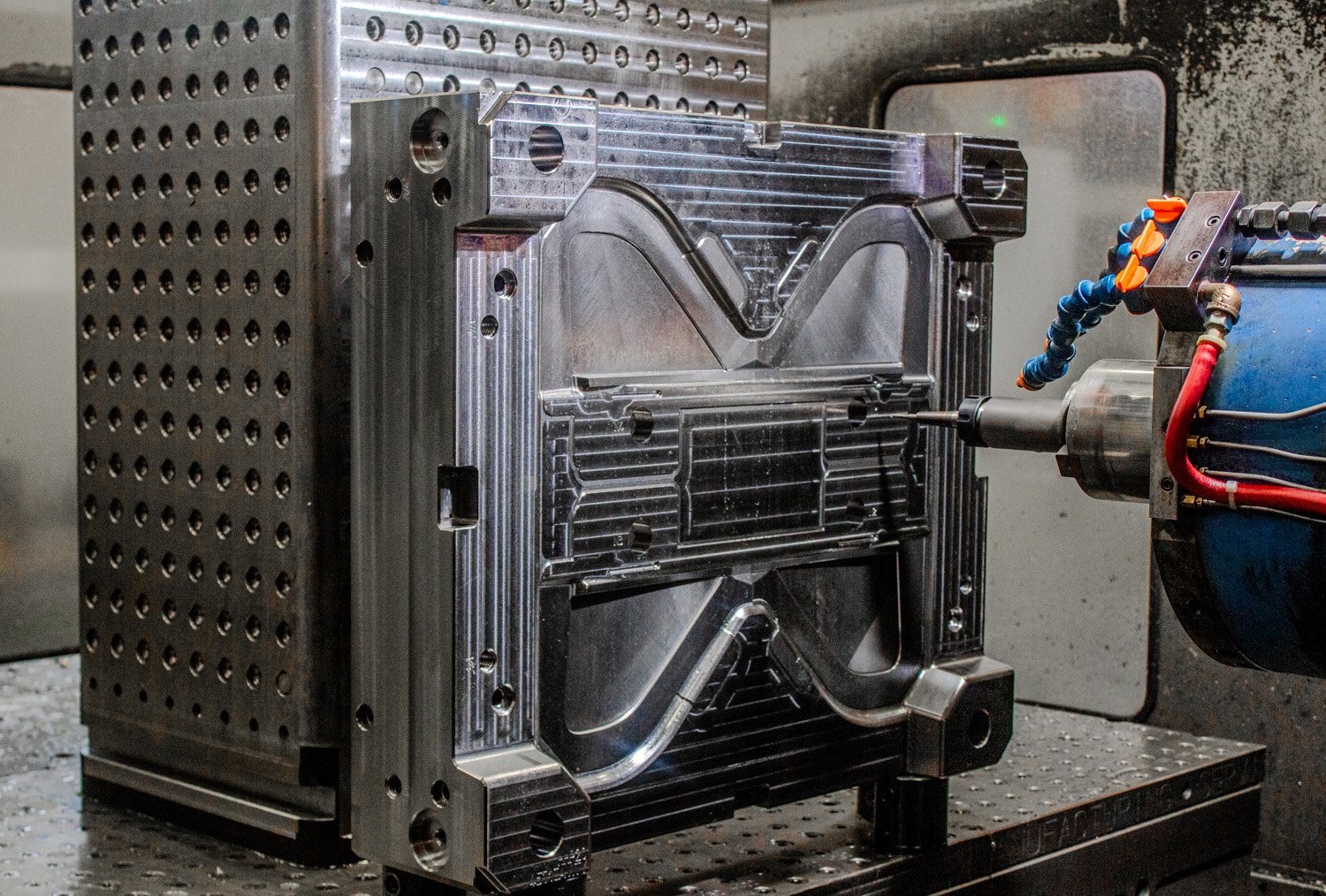

Prototype Molds

NextGen provides support for the rapid development and manufacturing of low-volume aluminum and steel prototype tools. Through our partnerships with local tryout facilities, we offer comprehensive services, including mold builds and low-volume production runs, delivering the necessary parts directly to your doorstep.

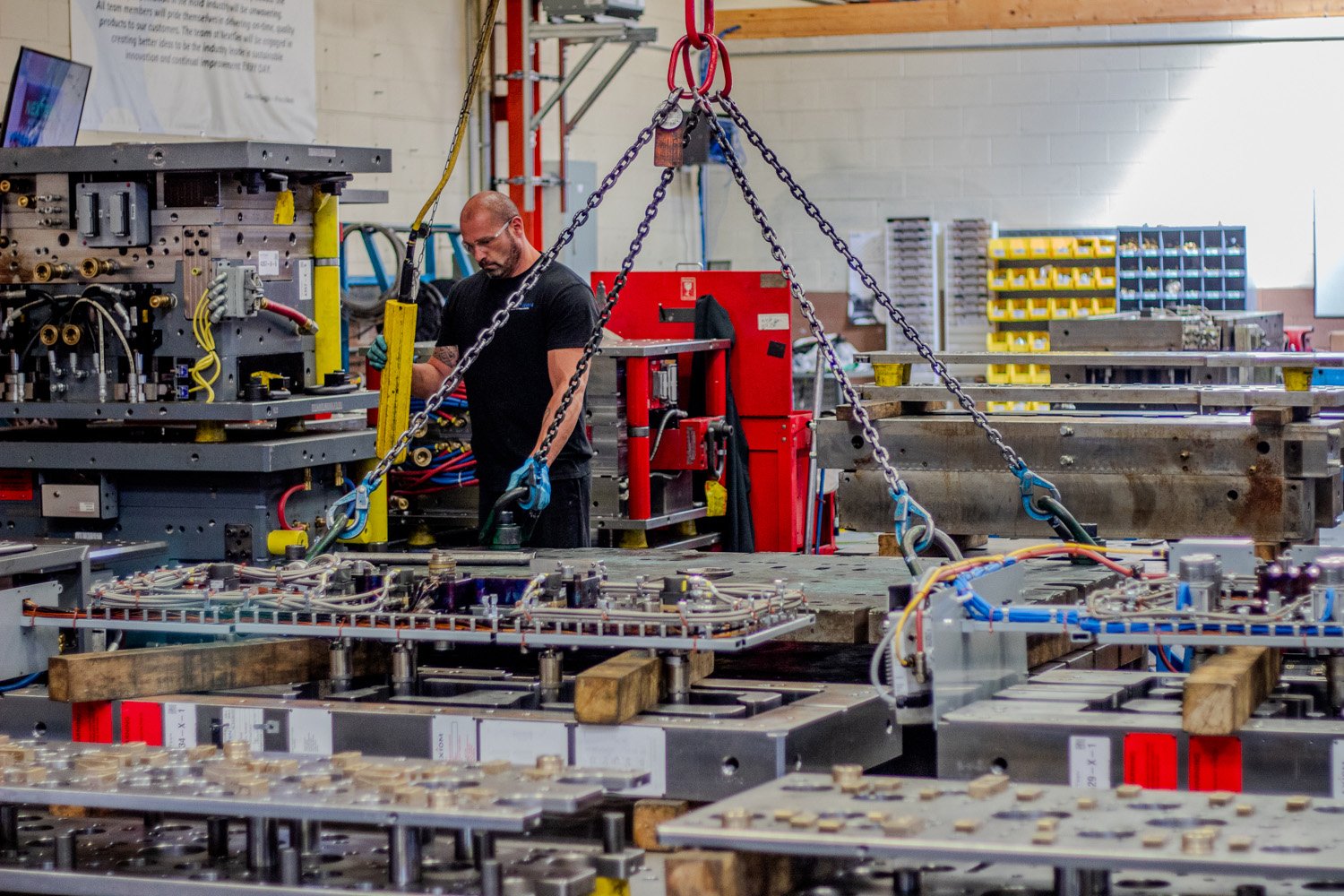

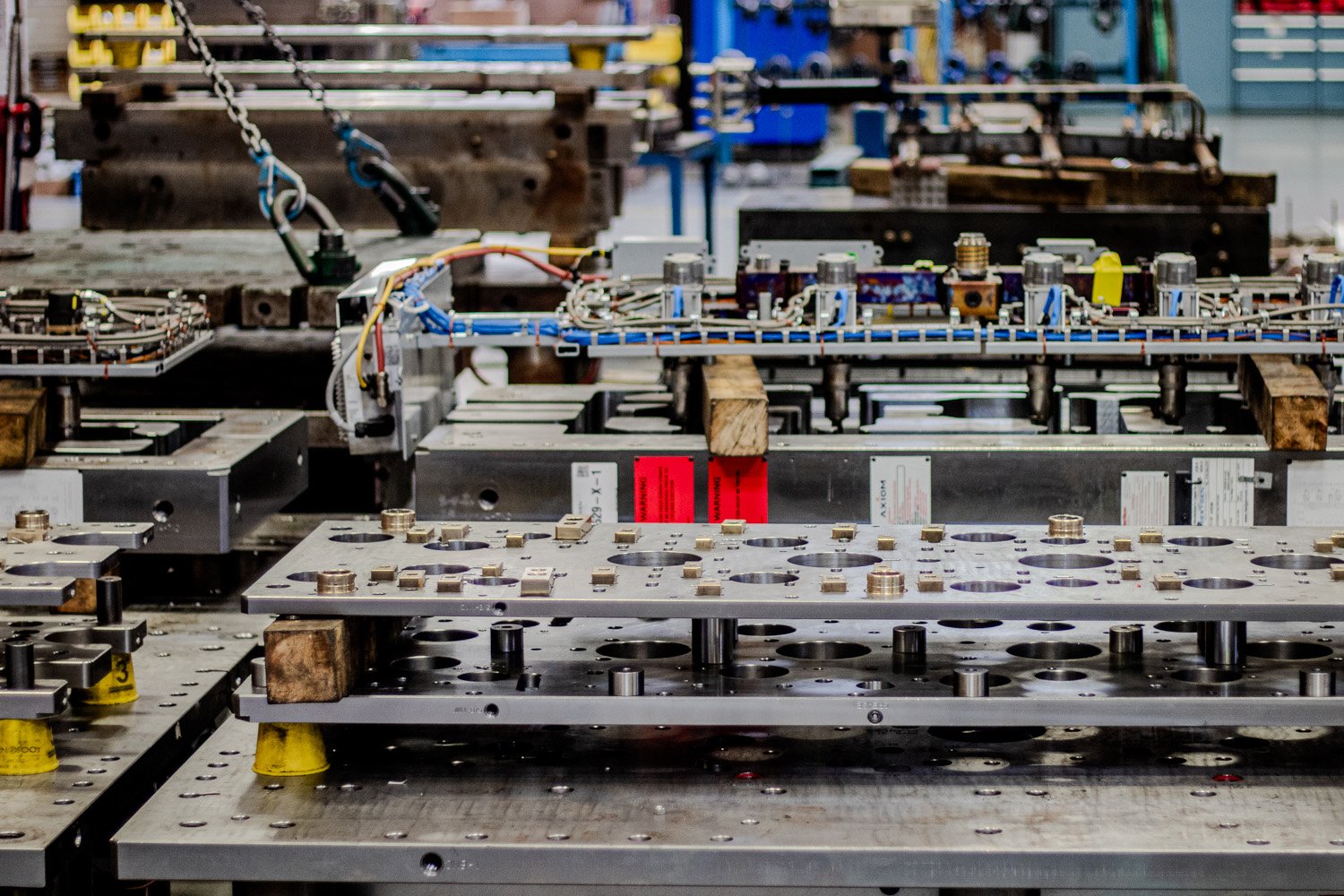

Production Molds

Feasibility to in-plant start up support, we specialize in standard injection molds, 2-shot molds, compression molds and steam molds.

Engineering Changes, Repairs & Maintenance

Our team is fully equipped to handle all types of modifications and repairs. Whether the tool is built by NextGen or not, we support our customers to ensure their tools run efficiently. In cases where no data is available, we can offer reverse engineering services to generate the necessary data and implement required changes. Additionally, we provide preventative maintenance plans to help minimize mold downtime and ensure tools operate at optimal cycle times.

Landing Support

Whether you’re a tool shop without a North American facility or a Tier One building overseas, we act as the local liaison. Our LCC team ensure tools are received in good condition, prepared for graining or trials, and provide support for the end user during startup.